Kuhn

Kuhn - SW 1114 C

-

ID # 34915397

- Back ID:34915397

- Book a Demo

- Get Directions

|

KUHN SW 14 Series bale wrappers can wrap large square bales, 2x3 or 3x3 (80x60-90 cm), up to 6’ (180 cm) in length, and round bales up to 5’ (150 cm) in diameter. KUHN wrappers rotate bales evenly for exact film overlap, and consistently and tightly wrapped bales. Choose from two different control systems, manual or computer controlled, to best suit your personal preference. The pre-stretchers, film cutters, wrapping table and low-profile chassis design make KUHN bale wrappers simple, easy-to-use, fast and efficient. KUHN bale wrappers, designed with you in mind, provide reliable performance to ensure optimum forage quality throughout the storage period. The KUHN SW 1114 is a 3-point mounted, quick-hitch compatible model ideal for “wrap and stack” operations in the field or in the yard. Wrapping at the storage site means less risk of film damage and can be done by a one-man operation. The wrapper can be operated from a loader while using a power pack or second tractor for the oil- and power supply due to the standard RF remote control. The KUHN SW 1614 is a trailed, self-loading bale wrapper suited perfectly for operations where high capacity and high efficiency are required. The automatic parallel loading arm, with standard round bale kit, ensures gentle, on-the-move bale loading in all weather conditions. Due to its unique low-profile chassis design with wide track wheels a second bale can be carried during wrapping to increase overall efficiency. |

|

Fast and Reliable Wrapping

The KUHN large square bale turntable wrappers are equipped with two pairs of steel rollers, with a ribbed profile, This design creates a deep and stable cradle for the bale, ensuring maximum bale traction, even bale rotation and proper film overlap, whatever the bale size. Two large bale support rollers provide additional stability and guidance. Round bales can also be wrapped with these wrappers. |

|

The standard pre-stretchers, which hold a 30” (750 mm) roll, are made of aluminum to avoid build-up of tack from the film. Both outer ends of the aluminum rollers are cone-shaped to maintain the optimum width of the film and reduce the risk of film tear. The special ribbed profile of the aluminum rollers keeps air and water away from the film. The location of the pre-stretchers makes it very easy to change the film rolls. The standard pre-stretch of 70% is reached by a low-maintenance and low-noise gear transmission. An optional 60% pre-stretcher gear kit can be installed to change the standard pre-stretch to 60%, rather than 70%, to adapt to difficult wrapping conditions. |

|

Once the desired number of film layers have been applied, the film is then held firmly and cut. A hydraulic, high-grip film cutter allows you to adjust the cutting moment independent of the table tipping position, resulting in the shortest possible end string. It has a long stroke to help accommodate various bale lengths, and ensures a firm hold and a clean cut of the film in various weather conditions. |

|

Gentle Bale Discharge

Low-Profile Chassis Design

Low-Profile Chassis DesignThe KUHN SW 1614 bale wrapper features a unique low-profile design ideal for stability when loading, wrapping or unloading a bale. The rear axle position results in a low table height eliminating the need for an active fall damper. There is constant weight transfer to the tractor that prevents up-and-down movements of the drawbar and prevents tractor wheel slippage when driving uphill with a bale on the table or loading arm. The bale can be dropped on the go for maximum output! |

|

The low mounted table on the SW 1114 ensures a gentle bale discharge so there is no need for a fall damper. The low mounted height also allows easy replacement of the film rolls. |

|

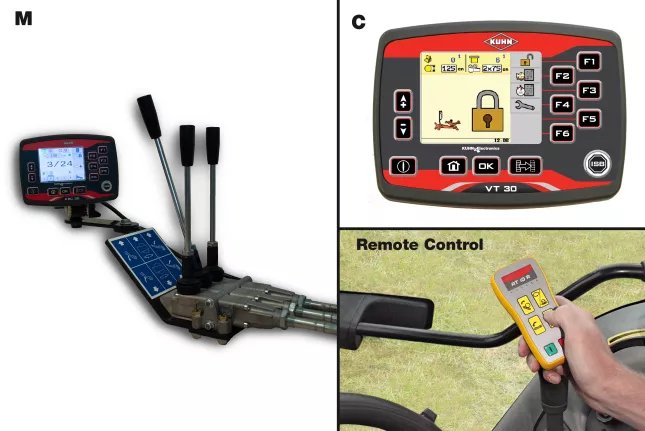

Manual or Computer Control

Two different control systems are available dependent on model and driver preferences: The manual version (M) is controlled with cable levers, and comes standard with the bale-and-wrap counter and autostop. The bale-and-wrap counter counts the film layers and total number of wrapped bales. The autostop function will automatically stop the wrapping table once the target number of film layers have been applied. This enables semi-automatic wrapping, even with manual controls. The computer-controlled version (C) uses a color touchscreen VT 30 to provide all the information and features of fully automatic wrapping. The SW 1114 computer-controlled version (C), with standard RF remote control, can be operated from a loader while using a power pack or second tractor for the oil- and power supply. This creates a one-person operation for loading, wrapping and stacking. Wrapping at the storage location means a minimum risk of damage to the film. The C version comes standard with automatic stop at the end of film roll or film tear, integrated bale and wrap counter, play/pause function and 90° loading position. The SW 1614 computer-controlled version (C), with integrated AutoLoad function, has increased overall efficiency and loading and wrapping capacity. The automatically controlled computer system can be equipped with an RF remote control to use the wrapper in a stationary application. |

|

The SW 1614 C can carry a second bale in the loading arm during wrapping. The AutoLoad function offers increased overall loading, wrapping capacity and efficiency. The patented AutoLoad function enables the operator to fully concentrate on the driving process, while the wrapping process is automatically started once the bale has been detected on the loading arm. Picking up a second bale with the loading arm, during the wrapping process for transport, is fully automated. |

| Download Brochure | Download |