Kuhn

Kuhn - VT 244 TRUCK

-

ID # 34915413

- Back ID:34915413

- Book a Demo

- Get Directions

|

KUHN Knight VT 200 Series twin-auger Vertical Maxx® mixers are ideal for small to medium dairy and beef producers looking to put a quality ration in front of their animals. The VT 200 Series features multiple improvements that will provide enhanced performance and longer, more reliable service. These updates include updated front conveyors, better door-to-floor sealing, heavier high-wear auger flighting, hydraulic disc brakes and EZ-mate scale system. The VT 200 Series mixers range in capacity from 320 – 760 ft3, and are available in trailer and truck configurations. Multiple configurations, single- or 2-speed drive options, along with multiple discharge options, allow machines to be tailored to every feeding operation’s needs. |

|

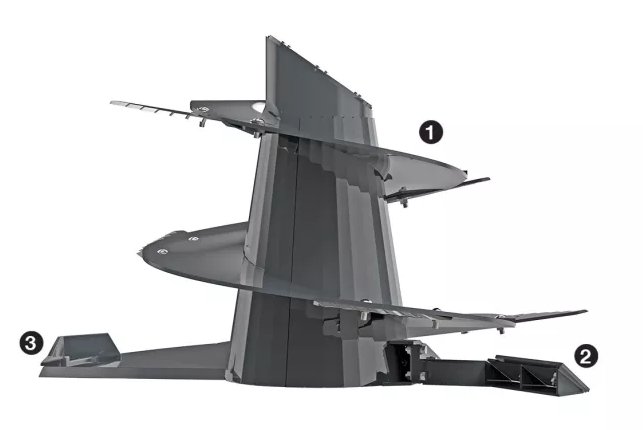

Superior Feed Movement

Cone-style augers provide superior feed movement for faster, more complete mixing and processing. The smooth, continuous auger flighting (1) creates a rolling feed action that improves mixing. The swept back kicker (2) is formed rearward to efficiently charge the door with feed the entire way on each pass for even discharge and decreased unloading time. The adjustable, replaceable lead-flighting scraper (3) is angled to guide feed up the auger flighting for efficient movement. |

|

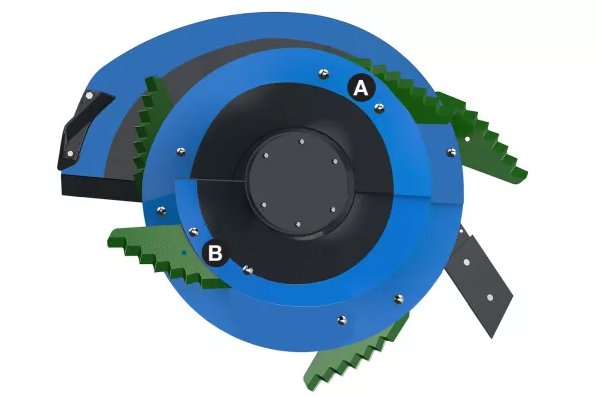

Large, 15” or 20”, replaceable hay cutting knives are available to best handle the material to be processed. The knives have two positions to adjust the aggressiveness of the knife angle. Versatility of knife length, angle and position allow for an optimal setting with a wide variety of ration ingredients. .

// A: Knife set in for slicing and cutting |

|

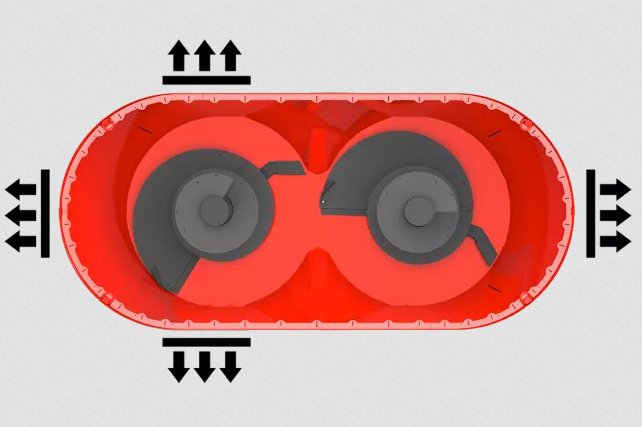

Improvements to the mixing chamber work in combination with the redesigned augers to increase feed movement. Straighter sides, smoother curves and steeper baffles help promote a fast, complete mix for a fluffy, palatable ration. No preprocessing or special loading is required for round or square bales making it easy to load and use. Faster auger speeds also provide quicker, more complete cleanout. |

|

The adjustable hay stops provide flexibility in processing to provide you with the cut length necessary to reach the optimal nutritional value you’re striving for. This adjustability makes hay processing more efficient and helps minimize overprocessing. |

|

Simple, Dependable Drive

Patented Split Drive

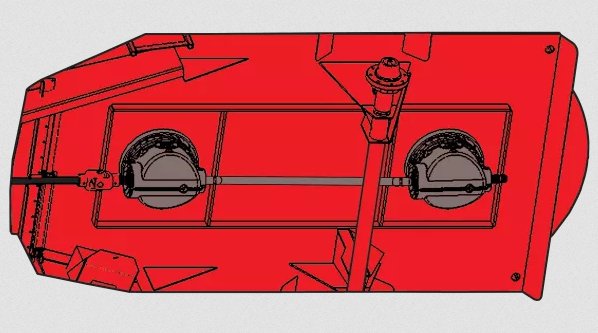

Patented Split DriveThe patented drive system on the VT 256 and 268 models consists of a 2-speed, split-drive gearbox, two planetary gearboxes and two torque-disconnect PTOs. This system provides reliable performance and long service life with a simple and quiet design. The 2-speed, split-drive gearbox provides the flexibility of high and low speeds without adding another gearbox. It allows for a lower horsepower and easier starting speed (28 rpm in low) while also having a high speed for fast mixing and more complete cleanout (41 rpm in high). The gearbox can be shifted manually on the machine or with an in-cab electric shift option for operator convenience. |

|

The twin planetaries are designed to provide dependable performance and long life. The drive systems allow the use of single-stage planetaries, which produces far less heat for easier cooling. |

|

Two automatically resetting torque-disconnect PTOs provide independent protection for each planetary. This helps guard against obstructions encountered by each individual auger, ensuring reliable service and longer life. |

|

Customers now have a choice of a single-speed or two-speed drive. A single-speed, split-drive gearbox is now offered on the VT 256 and 268 as a more price competitive option for those customers who do not require a low speed for startup. The single-speed option has an auger speed of 37 rpm at rated input speed. The 2-speed, split-drive gearbox is an effective box to provide customer flexibility with a low speed (27 RPM) and a high speed (40 RPM). The low speed allows for a lower horsepower start up and a high speed for mixing and a complete cleanout. |

|

VT 232 and VT 244 Models feature a straight-drive planetary system that provides simplicity for lower torque applications. |

|

Tailor to Your Operation

Various door configuration options on trailed models offer flexibility to fit a variety of feeding situations. The large discharge openings provide fast, even unloading from front, side and rear door locations for maximum efficiency. Choose a front door for clear visibility of the material coming out of the door. The front cross conveyor uses rugged components for unmatched dependability. A heavy-duty, steel floor on the VT 232-268, along with the heaviest conveyor chain in the industry, helps ensure long life and less down time. New discharge options provide the ultimate in versatility to match most feeding situations. Truck models offer a left-side door, while trailer models offer doors on either or both sides. The large openings allow fast unloading with comparable feed flow out of one door that many competitive machines get with two. A rear commodity door is available on VT 244-268 models. The large opening provides fast discharge, even with high-roughage premixes. A discharge tray is included on truck models to direct material flow for clean, accurate feed placement. |

|

To suit your operation’s needs, KUHN VT 200 Series mixers are available in a trailer or truck-mounted configuration. Trailer models are the most popular configuration as they are the most economical and versatile. Being detachable allows the tractor to be used elsewhere on the farm when not being used for feeding. Truck-mounted models are a suitable option for those that have to feed cows at several different locations, with large travel distances. This option allows a feeder to quickly get from the mixing location to the feed bunk and back again. |

| Download Brochure | Download |