Grégoire-Besson

Grégoire-Besson Rover 50

-

ID # 24836677

- Back ID:24836677

- Book a Demo

- Get Directions

The most ecological and sustainable weed control solution in the world.

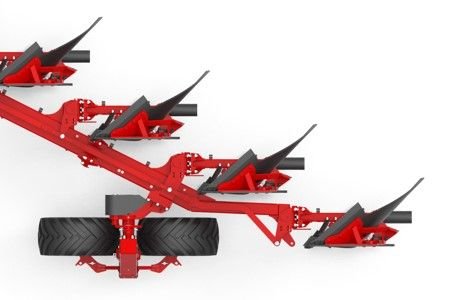

In-furrowDesigned for tractors with single wheels, in-furrow ploughs make ploughing easier. |

On-landOn-land mounted ploughs are generally recommended if your tractor is equipped with tracks, twin wheels or wheels over 710 mm wide. |

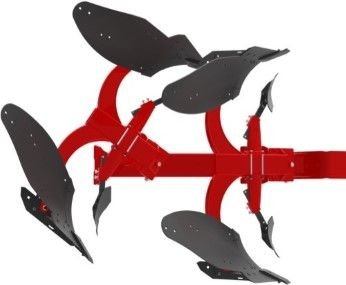

Mixed SkimmerThe short coulter and mouldboard make this combination very versatile. It is suitable for 80% of applications. |

Plastic Mixed SkimmerThe plastic mouldboard enables the surface to be scalped, even with very sticky soils. |

Universal SkimmerIts wider coulter and longer mouldboard enable this combination to handle larger volumes of plants than the mixed skimmer. |

Maize SkimmerThe high mouldboard guarantees a smooth passage through tall plants such as corn, sunflower, etc. |

Pasture SkimmerThe very long mouldboard enables it to turn over very dense root systems such as those found in grasslands. |

TrashboardUsed mainly in winter ploughing, it positions the residues of large plants vertically to improve water infiltration. |

Spring-mounted Disc CoulterSuitable for stony soils. It cuts plants and soil 10 cm in front of the body. It creates a clean furrow base and wall that provides better grip to the tractor. |

Bolted Disc CoulterSuitable for lightly stony soils. It cuts plants and soil 10 cm in front of the body. It creates a clean furrow base and wall that provides better grip to the tractor. |

Knife coulterIt cuts a strip of earth to stop the furrow wall attaching to the mouldboard and helps prevent it from crumbling. |

Mouldboard extensionThe mouldboard extension positions the earth for precise finishing. It limits wear at the end of the mouldboard. |

Spike Sub-soilerIt loosens the soil to a depth of 15 cm under the plough body. It promotes water infiltration, gas exchange and root exploration. |

Furrow openerThe furrow opener enlarges the furrow base so that track markers equipped with wide tyres have better grip. |

- 1.Compact, easy-to-handle, flexible....

- 2.Robust

- 3.Smart design

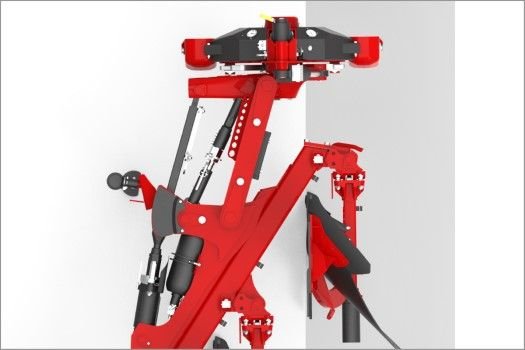

- 4.Available in-furrow or on-land

- 5.Compatible with different types of tractors

- 6.Forward centre of gravity, smooth lifting

- 7.Low drag, low fuel consumption

- 8.Wide choice of equipment for all types of soil

- 9.Self-aligning roller for consolidation

- 10.Excellent stability in the field and on the road

Multi-positionsIf your ploughing conditions do not vary significantly (plot contours, soil hardness, climate, crops, etc.), you do not need to change your working width frequently. In this situation, we recommend the multi-position system. |

Hydraulic vario widthIf your plough is used by different people (for example, in a cooperative) or if you use your plough in different conditions (for example, subcontracting or on farms with different soils and crops), we recommend the Vario system. |

Shear Bolt |

| For stone-free soils, choose shear bolt safety. If the ploughing element hits an obstacle (stone, root...), the shear bolt snaps. The entire element rotates, rises and allows the foreign body to pass under the plough. The shearing noise alerts you, so you stop the tractor, get off and extract the bolt that gave way. You replace the shear bolt and you’re ready to plough again.  |

| For light and sandy soils without any stones, we recommend light soil shear bolts. The way it works is the same except there are 2 bolts for each ploughing element, one per body. Shear bolt safety extends the life of your equipment: it limits frame bending and it reduces the forces exerted on your tractor. Safety shear bolts give way when the body tip resistance exceeds between 4.2 and 6 tonnes.  |

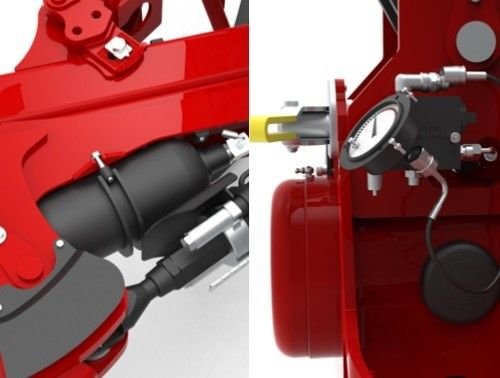

Continuous Hydraulics |

| If you plough fields with stony soil, the continuous hydraulic safety version is recommended. If a ploughing body hits a stone or any other foreign object, the entire element lifts up (up to 85 cm clearance) and lets the obstacle pass. Then the element returns to its place by means of the hydraulic jack. 4 ball joints ensure perfect support and positioning. You don’t need to get out of the tractor cab. You can plough without worrying. This safety system extends of the life of your equipment and maximizes productivity.  |

| For very stony and clayey soils, the Rover 60 and Rover 70 provide high-capacity continuous hydraulic safety. This is a similar system but more suitable for this type of soil. It means that you obtain very even and level ploughing. The safety system will not trigger in the most compacted areas of your soil. Whether you decide on hydraulic or high capacity hydraulic safety, you have a choice of 3 cylinder diameters: standard, large or very large diameter. The heavier the soil, the larger the diameter you should choose.  |

| You can also configure your hydraulic safety system by choosing between 100 bar or 150 bar pressure accumulators. The higher the pressure, the less often the safety system triggers. The continuous adjustment valve option allows you to calibrate the hydraulic safety activation in the cab. This option is really useful if you who work in very diversified plots.  |

Compact sizesWith optimised lengths, the first body being as close as possible to the tractor and with body spacing starting at 90 cm, the overall size of Rover mounted ploughs is reduced. |

1st Line OffsetYou can configure your 1st body to have a very large offset to reduce your working width and plough in areas that are difficult to work in. |

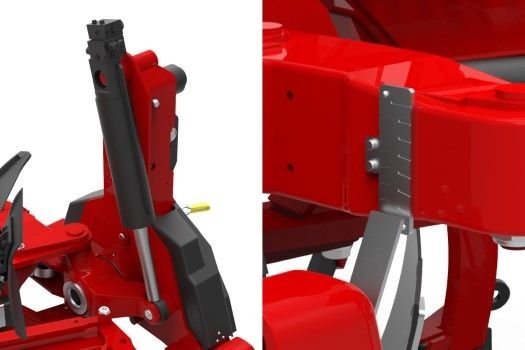

3rd Point SuspensionIn order to protect your back and reduce impacts on the tractor chassis and plough, the coupling 3rd point can be connected to a hydraulic system that absorbs shocks. |

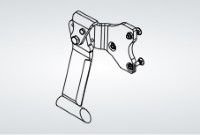

Hydraulic SwitchAll adjustments are made from the tractor cab even though there are only three double-acting spool valves. There is no need to have a large number of valves to benefit from all the plough’s functions. |

Robust ShaftsThe shaft is the heart of the plough. This is where the greatest number of forces are exerted. The bearings between the front axle and the shaft are distributed over a long length. |

Double FramesRover frames are extremely robust due to their thickness and tubular construction. |

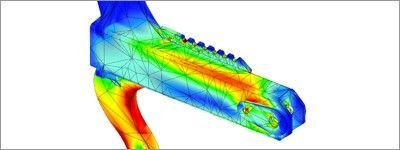

High-strength steelOur suppliers provide us with high-strength steels that are tested and verified. |

Finite Element AnalysisThe Grégoire Besson design office uses ’Finite Element Analysis’ (FEA) software. |

Protective CoversTo protect hydraulic hoses and other vulnerable components, we fit protective covers on the headstock to minimize impacts and soil accumulation. |

Independent Offset and TiltGrégoire Besson’s parallelogram system enables you to make independent fine adjustments between the offset and the tilt. |

Add or remove a bodyIf you plan to change your tractor for one with higher or lower power, you can add or remove a body which means you continue to profit from your investment without having to change ploughs. |

Z-beamFor more than 4 bodies, we offer Z-beam frames. |

Mechanical vertical plumbMechanical vertical plumb adjustment is ideal for in-furrow ploughing and for users who always plough at the same depth on uniform plots. |

Hydraulic vertical plumbHydraulic vertical plumb adjustment is also recommended for in-furrow ploughing, and if your plough is used at different working depths. |

The Rover has a forward centre of gravity, close to the hitch and tractor.

This makes the tractor easier to manœuvre and enables smooth lifting.

It is still heavy enough for good penetration into loose or compacted soils.

RJR WheelBack depth wheel |

PS WheelLateral depth wheels |

RT 10 WheelReinforced lateral depth wheel |

RTT 10 WheelLateral depth wheel & transport |

RLBM WheelLateral depth wheel and transport |

RLBH WheelLateral depth wheel and transport |

RTRH WheelLateral depth wheel and transport |

RCRH WheelLateral depth wheel and transport |

Body with bolt-on points |

Body with bar points |