Kuhn

Kuhn - RA 130 TRAILER

-

ID # 34915454

- Back ID:34915454

- Book a Demo

- Get Directions

|

Two new models have been added to the KUHN Knight RA 100 Series Reel Auggie® mixers – The RA 125 & RA 130. These 250 and 300 cubic foot machines continue the tradition of outstanding durability and performance, with proven features that stand out from the competition. After many requests from farmers like you, this capacity range of mixers is now available with the standard reel or the patented Helix reel. The Helix reel, with its open-concept design, offers faster, more consistent mixing and improved load leveling with any ration and excels mixing rations with high percentages of byproducts and/or roughages. The RA 125 and RA 130 are available in trailer, truck and stationary configurations. |

|

The Reel Advantage

The flexibility of choosing between a standard or Helix reel is a true advantage on the new RA 125 & RA 130. The standard reel does an excellent job mixing, but if you're mixing stickier or higher-roughage rations, the open-center Helix reel is your answer. The standard reel is a time-tested design going back to the original development of the reel mixers. This is the lower cost reel option and performs extremely well in free-flowing rations with a lower amount of roughage. The standard reel consists of a main center tube supporting four spring-loaded straight bars. The springs serve as protectors from obstructions to both the reel and the side wall. Poly wipers on two of the bars assist with cleanout especially with granular, free-flowing materials. |

|

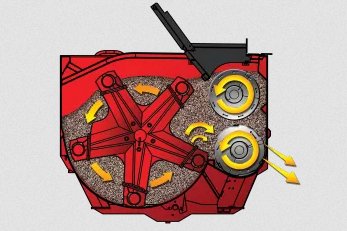

The Helix® reel has a robust build and has been thoroughly tested to withstand the most challenging conditions. The design of the reel crossbars evens the pressure across the length of the reel for smoother operation. It also engages with the feed more smoothly. The open-center design eliminates obstructions in the reel and provides superior feed movement and unparalleled mixing action. The benefits are unmistakable, with faster, more consistent mixing, improved load leveling, optimized mixer space utilization and fewer dead spots for the ultimate in ration quality. A mix bar runs diagonally across the center of the reel to help ensure consistent feed movement throughout the entire mixing chamber. The reel crossbars keep feed moving efficiently around the outside of the chamber. The secondary mechanical mixing action from the mix bar provides a fast and thorough mix even in wet, heavy rations with large amounts of distillers grains. |

|

The reel thoroughly mixes rations gently without causing excessive damage to the feed ingredients, providing desired particle length in the TMR. The large reel gently lifts material up into the side augers for excellent side-to-side movement. The upper auger moves material rearward, while the lower auger moves material forward for end-to-end mixing. This helps feed continually charge the door during discharge. |

|

Quality performance, with the lowest possible input costs is the goal of every operation. The fast, gentle mixing of KUHN Knight reel mixers helps maximize efficiency and minimize expense. The reel and auger design eliminates much of the force and pressure seen with other mixer types, resulting in low horsepower requirements and, correspondingly, less fuel consumption for economical operation. |

|

KUHN Knight reel mixers provide a consistent mix, even with small batches, for a balanced ration from beginning to end. Their quick, even discharge with a more complete cleanout helps save time and maximizes efficiency. |

|

Designed with You in Mind

Front Oil Bath

Front Oil BathThe easy-access front oil bath on the RA 125 & RA 130 keeps drive chains lubricated and ensures a long drive life. Improved sealing eliminates oil leaking out the panel and door keeping the machine clean. Two quarter-turn door locks make accessing the oil bath and drive easy, compared to the old wingnut-style holding system. The roller chain drive is durable enough to handle batches with the heaviest, wettest, stickiest rations. Spring-loaded chain tensioners ensure proper chain tension and alignment. The rugged chain continuously runs through the enclosed oil bath, constant lubrication leads to added protection and longer life. |

|

Auger shafts on both the upper and lower augers are fused to the auger drive flange with a weld, providing a weld joint as strong as the shaft. This results in superior strength and durability over other conventionally welded shafts. |

|

With a high discharge point, these mixers allow for the use of a simple slide tray in most feeding situations. The long tray makes it easy to feed deeper into most bunks while preventing feed loss from the wind. This dependable, low-cost option also results in less maintenance. |

|

The door discharge and pivot have been redesigned and strengthened for extended service life. The linkage incorporates two ball pivots for smooth operation. |

|

Tailor Your Machine

To best suit your feeding needs, you can choose from a slide tray, chain and slat conveyor, or a 3-auger discharge to be equipped on your RA 100 Series mixer.

Slide Tray

Chain and Slat Conveyor

3-Auger Discharge

|

|

To suit your operation’s needs, KUHN Knight RA 125 & 130 mixers are available in trailer, truck-mounted or stationary configurations. Trailer models are the most popular configuration as they are the most economical and versatile. Being detachable allows the tractor to be used elsewhere on the farm when not in use for feeding. Truck-mounted models are a suitable option for those that have to feed cows at several different locations, with large travel distances. This option allows a feeder to quickly get from the mixing location to the feed bunk and back again. Whether mixing wood chips or a ration for your livestock, KUHN Knight RA 100 Series stationary mixers are ideal for maximizing feeding efficiency and mixer throughput on any operation. Stationary mixers are perfect for producers with centralized feed storage that are looking to deliver a final product by a method other than bringing the mixer to the final destination. This could include- belt delivery, truck delivery, or a variety of other options. |

| Download Brochure | Download |