Kuhn

Kuhn 8050-25

-

ID # 34915750

- Back ID:34915750

- Book a Demo

- Get Directions

| The KUHN Krause Interceptor® 8050 delivers high-speed tillage to control stubborn, chemical resistant weed growth, while sizing and evenly distributing tough residue into the worked soil profile. This action not only kills weeds and limits potential movement of wind driven residue, but also contributes to residue breakdown throughout the year and builds soil organic matter. Featuring independently mounted Excalibur® CT (Conservation Tillage) blades, adjustable, center-mounted tines, and the proven Star Wheel™ treaders with 24/7® finishing attachments, the Interceptor delivers a consistent, uniform field finish. |

|

Residue Incorporation

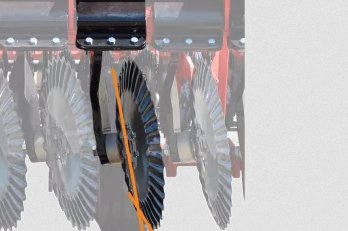

North American agronomy practices, like increased seeding rates, GMO hybrids and even varying soil moisture conditions must be reliably managed. The Interceptor’s depth-of-frame design provides ample distance for residue and soil flow between two parallel rows of 22-inch diameter, 32-flute Excalibur CT shallow concavity blades on 9” spacing. Each blade assembly is individually mounted on a compound angle with 6-bolt hubs and configured into a tandem design. The tandem blade configuration provides a consistent and uniform line of draft for high-speed implement tracking. This tandem design also contributes to a more uniform distribution of soil and residue verses competitive “offset disc” designs that can move residue and soil in a single direction. |

|

Compound blade angles have been developed and incorporated to provide optimum soil penetration without applying excessive backside blade pressure to the soil. Ample fore-to-aft space exists between the front and rear rows of blades to allow high-speed soil and residue flow to settle before contacting the rear row of blades. Heavy soil and residue flow from the front blades of close-coupled competitive designs can potentially slow or stall the rotation of the rear blades, causing a “plug” or unevenness in the finished seedbed. |

|

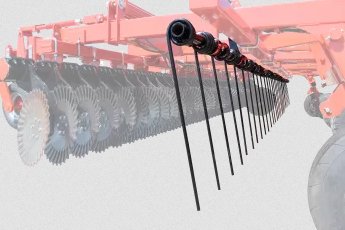

Center-mounted HD tines incorporated into the frame area immediately behind the first rank of Excalibur® CT blades maintain full contact with the soil surface to initiate residue redistribution and soil leveling. The single row of 5/8” diameter x 30” length x 12” spaced tines feature adjustable angles to force residue and soil flow from the front blades downward, settling loose material before contacting the rear row of blades and finishing attachment. |

|

Quality Finishing

Star Wheel™ treader gangs, mounted on 6-degree angles, level the seedbed and size clods, while mixing and anchoring residue into the loose soil. Constant-flow hydraulic down pressure on the Star Wheel treader allows the attachment to maintain even working pressure across a varying field surface, resulting in a consistent, uniform finish. Many competitive units depend upon their rear attachment to control machine operating depth and thereby transmit significant weight to their rear attachment, which can result in a tight, compressed seedbed. |

|

Available with flat blades for maximum clod sizing in hard soil conditions or round bars for increased soil firming in loamy soil conditions, this effective component completes a superior finish to any field. |

|

Maintenance-Free Bearings

|

| Download Brochure | Download |