Grégoire-Besson Voyager S70

Highly productive ploughs: fewer passes and optimized fuel consumption ...

- Overview

- Specifications

- Gallery

- ploughing in-furrow or ploughing on-land?

- multi-position or vario?

- a choice of 2 safety systems

- smart design

- precise ploughing from 15 to 40 cm deep over different working widths.

- the benefits and agronomical advantages of ploughing

- which type of body should i choose?

- mouldboards for bodies with bolt-on points

- skimmers, trash boards, disc coulters, etc.

- recap

- Videos

Overview

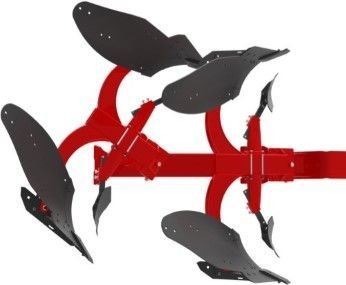

Highly productive ploughs:

fewer passes and optimized fuel consumption.

Specifications

Gallery

ploughing in-furrow or ploughing on-land?

In-furrowSuitable for small to medium tractors, in-furrow ploughs make ploughing easier. |

On-landOn-land ploughs are suitable for high power tractors, including tracked, twin wheels or wheels over 710 mm in width. By working on-land, tyre wear is reduced, especially on flinty soils. |

multi-position or vario?

Multi-positionsIf you always work with the same conditions (soil, plot layout, climate, crops, etc.), you probably won’t need to change your working width often. |

VarioFor ploughs used by several people (for example, in a cooperative) or when you have to plough in varying conditions (subcontracting, farms with different soils or crops, different terrains, etc.), we recommend the Vario system. |

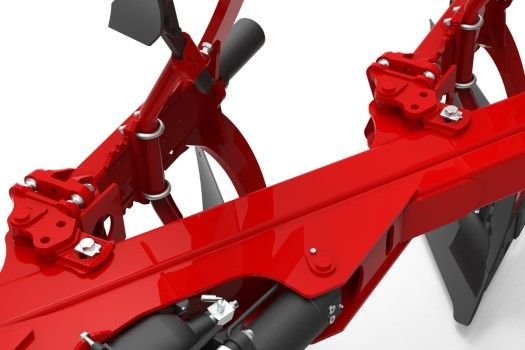

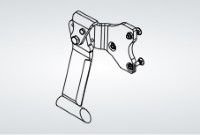

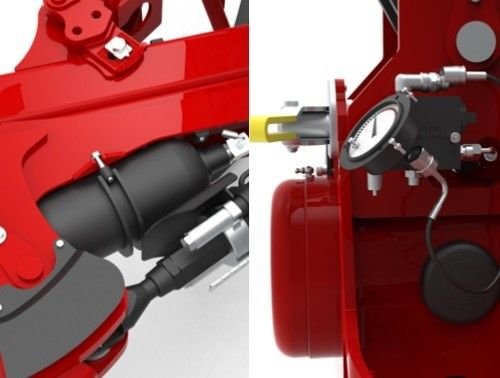

a choice of 2 safety systems

Bolt |

| If your soil is not stony, you can choose the shear bolt safety system. If you hit a foreign body, the shear bolt gives way, the ploughing element rises and lets the object pass. The shearing noise alerts you, so you stop and extract the sheared bolt. Simply replace the shear bolt and start ploughing again. If you happen to hit an obstacle, this safety feature prevents damage to your plough or tractor. The shear bolts give way when a force of between 4.2 and 6 tons is exerted at the tip, depending on the height of the elements and the type of bolt used.  |

Non-Stop Hydraulic |

| If you have stony soil, we recommend non-stop hydraulic safety. If you hit a foreign body, the ploughing element rises (up to 85 cm) and lets the object pass. After, the safety cylinder returns the element to its position. The 4 ball joints guide the element’s support and reinstallation You don’t have to leave the cab, you can continue ploughing without worrying about stones. This type of safety extends the service life of your replacement parts as well as your plough. You can be assured of long equipment life and maximum productivity.  |

| For very clayey and stony soils, we recommend high capacity non-stop hydraulic safety. This will enable you to have perfectly levelled ploughing because it restricts activation of the safety system in the most compacted soil areas. Whether you need the hydraulic or the high capacity hydraulic safety system, you can choose between 3 cylinder diameters: standard, large or very large. The heavier your soil, the larger the diameter you will need.  |

| Finally, you can fine-tune your hydraulic safety configuration by choosing 100 or 150 bar pressure accumulators. Here too, the more your soil drags your plough, the higher the pressure we recommend. If your plot’s soil structure is very uneven, you’ll be interested in the continuous pressure adjusting valve option. You can adjust the hydraulics directly from the tractor cab.  |

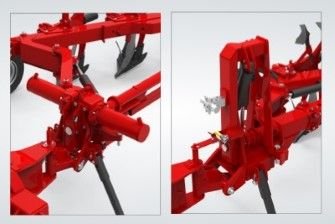

smart design

Smooth turningTurning your plough can be stressful. Whether you have the rack and pinion system or the double cylinder system, the Voyager can be turned smoothly even at the tipping point. |

Rear lifting or articulationOn the carriage models, the rear lifting jack allows you to deal with headlands smoothly and perform delicate manœuvres. |

110 articulated headstockVoyager’s 110 headstock articulation gives you optimum manoeuvrability. Comfortable and efficient on plots with complex geometry, it enables you to perform short and fast headland manœuvres. |

Z-beamThe Voyager Z-shaped beam on single wheelers means that the wheel passage is covered by the last body. In addition, this beam allows the chassis to pass close to the wheel when turning. |

Load transferOn rack and pinion models, you can fit a load transfer cylinder that enables you to shift weight to the rear of the tractor to give better traction. |

OffsetOn Voyager, the hydraulic offset management enables you to adapt to tractor tracks from 1.3 to 4.7 m width. This hydraulic adjustment offers you a precise, simple and efficient setting. |

Adding or removing a bodyIf you change to a higher or lower power tractor, you can add or remove a ploughing body. Remember to specify this when configuring your plough. You don’t have to change ploughs when you change tractors. |

Simple settingsYou can set the working depth in 3 places: the tractor lift at the front, a stop screw on the carriage (depending on the model) and another on the depth wheel. To adjust tilt, simply adjust the stop screws located either side of the headstock. That’s it, you’re ready. |

Hydraulic controlsWith the hydraulic selector you can have up to 6 hydraulic controls in the cab even if you only have 3 hydraulic valves on your tractor. |

Positioning the ploughWhen you’re manoeuvring in headlands, turning the plough one way then the other helps you to position it. This means you can position and guide it exactly where you want. |

precise ploughing from 15 to 40 cm deep over different working widths.

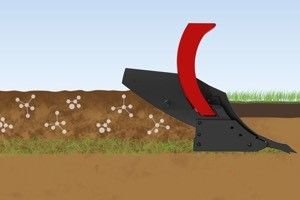

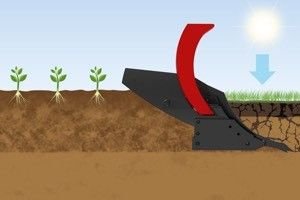

Crumbled ploughingThe step before seedbed preparation

If you are about to plant a crop, crumbled ploughing enables you to mix the material just before passing with a seedbed preparer. |

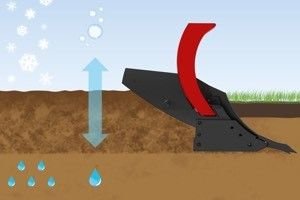

Over winter ploughingLet water and oxygen enter the soil

If you need to do winter ploughing, especially in clayey soils, it can be valuable to do deeper, high furrow ploughing. This allows you to channel the water, which during winter will turn into frost and break up the ground. |

the benefits and agronomical advantages of ploughing

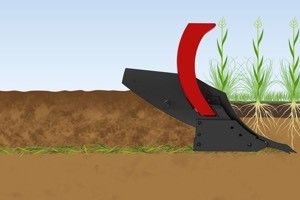

Soil structurePloughing improves soil structure. By turning and loosening the soil, ploughing allows air and water to circulate. |

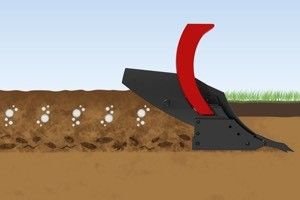

BurialPloughing allows you to introduce organic fertilizers into the soil (manure, slurry, residues, plant cover, grassland...) |

Weed controlPloughing buries weed seeds deep enough so that they do not germinate and then compete with your crop. |

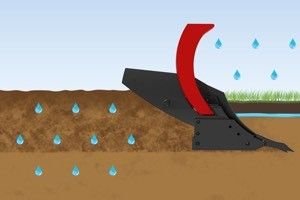

Water flowPloughing allows water to infiltrate and circulate freely and so limit retention. |

Extreme weatherWhen droughts or heavy rains prevent straightforward cultivation, ploughing provides a viable solution. |

MineralizationPloughing makes nitrogen less volatile by trapping it in the soil which accelerates mineralization. |

which type of body should i choose?

Body with bolt-on points |

Body with bar points |

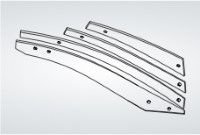

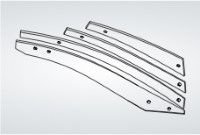

mouldboards for bodies with bolt-on points

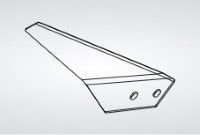

Helico-cylindrical AR5HMouldboard for moulded ploughing from 18 to 27 cm deep in all types of soil. Suitable for cutting widths from 14 to 18’’ (35 to 45 cm). |

Long Helicoidal AR8HLMMouldboard for moulded ploughing from 22 to 32 cm deep in clayey and silty soils. Suitable for cutting widths from 16 to 22’’ (40 to 55 cm). |

Short Helicoidal AR4HMouldboard for moulded ploughing from 18 to 25 cm deep in all types of soil. Suitable for cutting widths from 12 to 16’’ (30 to 40 cm). |

Helicoidal E7This mouldboard is designed for moulded and very deep ploughing from 28 to 38 cm deep for all types of soil. Suitable for cutting widths from 14 to 18’’ (35 to 45 cm). |

Long Helicoidal H6Mouldboard for moulded ploughing 15 to 20 cm deep in clayey soils. Suitable for cutting widths from 16 to 20’’ (40 to 50 cm). |

Long Helicoidal H8Mouldboard for moulded ploughing from 18 to 30 cm deep in clayey soils. Suitable for cutting widths from 18 to 22’’ (45 to 55 cm). |

Long Plastic Helicoidal H8Mouldboard for moulded ploughing in stone-free and very sticky clayey soils. |

Cylindrical C16SMouldboard for crumbled ploughing from 20 to 30 cm deep in sandy, silty and clayey soils. Suitable for cutting widths from 14 to 20’’ (35 to 50 cm). |

Cylindrical C14SMouldboard for crumbled ploughing from 20 to 30 cm deep in sandy, silty and clayey soils. Suitable for cutting widths from 12 to 16’’ (30 to 40 cm). |

Helico-cylindrical M1Mouldboard for ploughing 15 to 22 cm deep in chalky and sticky soils. Suitable for 12 to 16’’ (30 to 40 cm) cutting widths. |

Slatted CV7 10Helicoidal mouldboard for ploughing 20 to 30 cm deep in heavy soils. Suitable for cutting widths from 35 to 55 cm. The blades can be replaced individually for greater savings. |

Slatted CV9 12Helicoidal mouldboard for ploughing 22 to 35 cm deep in heavy soils. Suitable for cutting widths from 35 to 55 cm. The blades can be replaced individually for greater savings. |

skimmers, trash boards, disc coulters, etc.

Mixed SkimmerThe short coulter and mouldboard make this combination very versatile. It is suitable for 80% of applications. |

Plastic Mixed SkimmerThe plastic mouldboard enables the surface to be scalped, even with very sticky soils. |

Universal SkimmerIts wider coulter and longer mouldboard enable this combination to handle larger volumes of plants than the mixed skimmer. |

Maize SkimmerThe high mouldboard guarantees a smooth passage through tall plants such as corn, sunflower, etc. |

Pasture SkimmerThe very long mouldboard enables it to turn over very dense root systems such as those found in grasslands. |

TrashboardUsed mainly in winter ploughing, it positions the residues of large plants vertically to improve water infiltration. |

Spring-mounted Disc CoulterSuitable for stony soils. It cuts plants and soil 10 cm in front of the body. It creates a clean furrow base and wall that provides better grip to the tractor. |

Bolted Disc CoulterSuitable for lightly stony soils. It cuts plants and soil 10 cm in front of the body. It creates a clean furrow base and wall that provides better grip to the tractor. |

Knife coulterIt cuts a strip of earth to stop the furrow wall attaching to the mouldboard and helps prevent it from crumbling. |

Mouldboard extensionThe mouldboard extension positions the earth for precise finishing. It limits wear at the end of the mouldboard. |

Spike Sub-soilerIt loosens the soil to a depth of 15 cm under the plough body. It promotes water infiltration, gas exchange and root exploration. |

Furrow openerThe furrow opener enlarges the furrow base so that track markers equipped with wide tyres have better grip. |

recap

- 1.Compact, easy-to-handle, flexible....

- 2.Robust

- 3.Smart design

- 4.Available in-furrow or on-land

- 5.Compatible with different types of tractors

- 6.Forward centre of gravity, smooth lifting

- 7.Low drag, low fuel consumption

- 8.Wide choice of equipment for all types of soil

- 9.Self-aligning roller for consolidation

- 10.Excellent stability in the field and on the road