New Holland Loader Backhoes - B95D

HORSEPOWER, NET HP (KW) 95 (71) MAX OPERATING HEIGHT, FT/IN (MM) 17’ 5” (5318) STANDARD COMFORT AND VISIBILITY A new cab design with more space, new rear side windows, vastly improved clearance when turning the seat, and hugely improved in-cab storage capacity guarantees increased operator productivity ...

- Overview

- Specifications

- Gallery

- engine and chassis

- axles and transmission

- technical specifications

- literature

Overview

|

HORSEPOWER, NET HP (KW) 95 (71) MAX OPERATING HEIGHT, FT/IN (MM) 17’ 5” (5318) STANDARD | |

COMFORT AND VISIBILITYA new cab design with more space, new rear side windows, vastly improved clearance when turning the seat, and hugely improved in-cab storage capacity guarantees increased operator productivity. | |

HIGH VERSATILITYThe D Series loader backhoes offer versatility with their wide range of attachments that help the operator take on tougher jobs. | |

POWERSHIFT™ OR POWERSHUTTLE, IT’S YOUR CHOICE.D Series loader backhoes come with switchable two- or four-wheel-drive, a powershuttle forward/reverse mechanical transmission, or the automatic PowerShift™ transmission. | |

HYDRAULIC POWERD Series loader backhoes are offered with either a twin gear pump (mechanical controls) or a variable placement pump (pilot controls). An auxiliary hydraulic circuit is available to power attachments such as hydraulic breakers and soil augers. |

Specifications

Gallery

engine and chassis

POWERFUL ECONOMYDeveloping 74 to 110 hp depending on the model, the new FPT Industrial F5 3.4-liter, four-cylinder engine is the same unit proven in New Holland T5 tractors. Compliant with stringent Tier 4 Final emission regulations, the engines have an advanced throttle control system that allows the operator to adjust how the engine responds to throttle inputs from smooth to fast. New D Series models also feature three, new fuel-saving modes to increase economy and reduce wear and tear on the machine. |

POWERED BY FPT INDUSTRIAL

|

COMPACT HI-ESCR AFTER-TREATMENT EMISSION SYSTEM

|

YOUR PERFECT WORKING PARTNER |

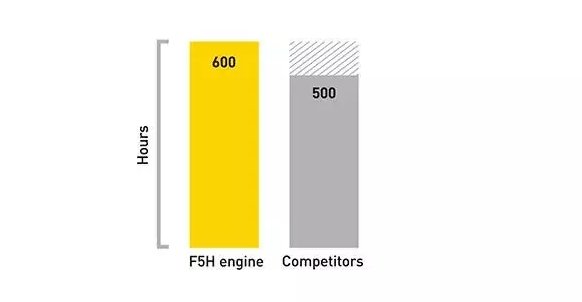

MORE TIME WORKING

|

CHASSIS

|

axles and transmission

POWERSHIFT™ OR POWERSHUTTLE, YOU DECIDED Series loader backhoes come with switchable two- or four-wheel-drive, a powershuttle forward/reverse mechanical transmission, or the automatic PowerShift™ transmission. All PowerShift models now feature a convenient F-N-R switch on the front loader multifunction lever. |

THE RIGHT FRONT AXLE FOR THE JOB |

THE RIGHT REAR AXLE FOR THE JOB |

MECHANICAL FOUR-SPEED POWERSHUTTLE |

technical specifications

|

Blade width, ft/in (mm) |

7' 5" (2248) |

|

Stabilizer spread, operating, ft/in (mm) |

10' 7" (3226) |

|

Max grading angle |

116 |

|

Linkage geometry |

Straight |

|

Base Unit (4WD, Cab) |

17,560 lbs |

|

With options added Canopy |

-397 lbs |

|

Make and model |

F5BFL413B*B |

|

Type |

Tier 4 Final certified, Diesel Oxidation Catalyst with Urea Dosing Module and Selective Catalytic Reduction, HPCR, 4-cycle diesel |

|

Aspiration |

Turbocharged Aftercooled |

|

Rated RPM |

2200 |

|

Number of cylinders |

4 |

|

Displacement, cu in (l) |

207 (3.4) |

|

Horsepower, gross, hp (kW) |

97 (72) |

|

Horsepower, net hp (kW) |

95 (71) |

|

Peak torque, lb-ft (N-m) @ RPM |

338 (452) @ 1400 |

|

Transmission type |

Synchromesh |

|

Gear |

4F / 4R |

|

Max Fwd travel speed, mph (kph) |

22.5 (36.2) |

|

Brakes |

Less brakes, split brakes |

|

2WD curb clearance |

13' 6", 12' 7" |

|

4WD curb clearance |

15' 9", 11' 5" |

|

2WD bucket clearance |

17' 9", 16' 8" |

|

Max operating height, ft/in (mm) |

17’ 5” (5318) Standard |

|

Bucket rotation (max) |

200 |

|

Type |

Standard, Retracted, Extended |

|

Bucket digging force, lbs (kg) |

12,933 (5866), 12,933 (5866), 12,933 (5866) |

|

Crowd digging force, lbs (kg) |

8588 (3895), 8100 (3674), 5782 (2623) |

|

Boom lift @ -8 ft, lbs (kg) |

3234 (1467), 2738 (1242), 2332 (1058) |

|

Dipper lift @ +10 ft, lbs (kg) |

5342 (2423), 5831 (2645), 3885 (1762) |

|

Main pump type |

Dual gear |

|

Alternator output |

160 amps |

|

Battery capacity (std/opt) |

1200/900 CCA |

|

Hydraulic tank, gal (l) |

13.4 (50.7) |

|

Engine oil |

500 hours |